We bought a set of knives a while back that turned out to be too long for the knife block we had at home, and the longer knives would protrude through the bottom of the block and potentially scratch the bench top.

As a work-around solution until now we’ve had a wad of paper towel under the block, but now that I have a Problem Solving Machine we can do better.

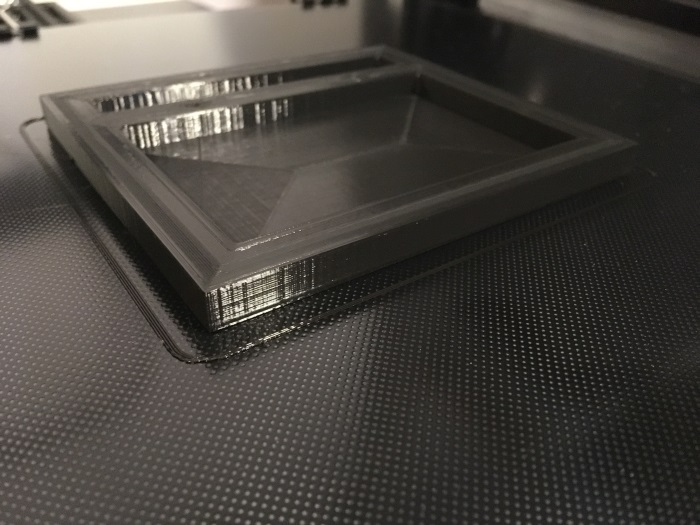

I created this simple design in Fusion360 to provide additional clearance under the block so that the longer knives would hang freely. The cross-bar was supposed to have two countersunk holes for screws but on my last iteration I accidentally blocked them up and didn’t notice so after printing I gently drilled countersink holes into the base.

This was the first print on my new Ultrabase and it worked much better than the standard glass base, however there was still a tiy bit of lifting on one corner. On my next print I will try a lower bed temperature to see if that helps.

I’m happy with the result of this print. I haven’t tried TPU yet but I think it might have been a better choice than PLA for this application. Once I get around to trying TPU I may try reprinting it.